Dónal Ó Coisdealbha analyzes the history and results of the management and production system (TPS) developed by the Toyota Motor Corporation, arguing that the cooperative effects the TPS had on Toyota’s internal labor relations contain the seeds of a successful model of socialist industrial production. Ó Coisdealbha is the director of process control, smart and digital development at a factory owned by a multinational electrical equipment manufacturer who is currently co-authoring a book with Tom O’Brien on labour time planning. His blog can be found here.

Introduction

This piece is a discussion of the social relations of modern industrial production and what it means for socialism. I believe this is important because the literature around socialist economics and planning tend to focus on abstract models of how production might work, without much emphasis on how it currently works and why. My conclusions may be surprising to the reader, although, in light of the information I’ll present, I think they should be regarded as common sense. For instance, I will explain that what socialists would immediately recognize as cooperative relations of production are already understood to be highly desirable by today’s industrial planners, although, of course, they do not express it in those terms. An appreciation of this and related facts allow us to refocus away from abstractions such as ‘planning’ and ‘competition,’ and instead to think about the changing nature of the content of those terms.

In this piece I will explain why necessary technical changes in planning tend to be complemented and optimized by changing the social relations of labor within the enterprise, and how capitalists have reacted to this reality by both experimenting with cooperative working conditions while also trying to find ways to avoid them. I will discuss the conclusions which can be drawn from these emergent features of the production system–namely that capitalist imperatives act as a fetter on the further development of industry. Using the lens of how existing industry works, it is possible to see how an economic system composed of generalized cooperative relations of production would have huge inherent superiorities over an economy based on private production processes.

The Development of the Toyota Production System

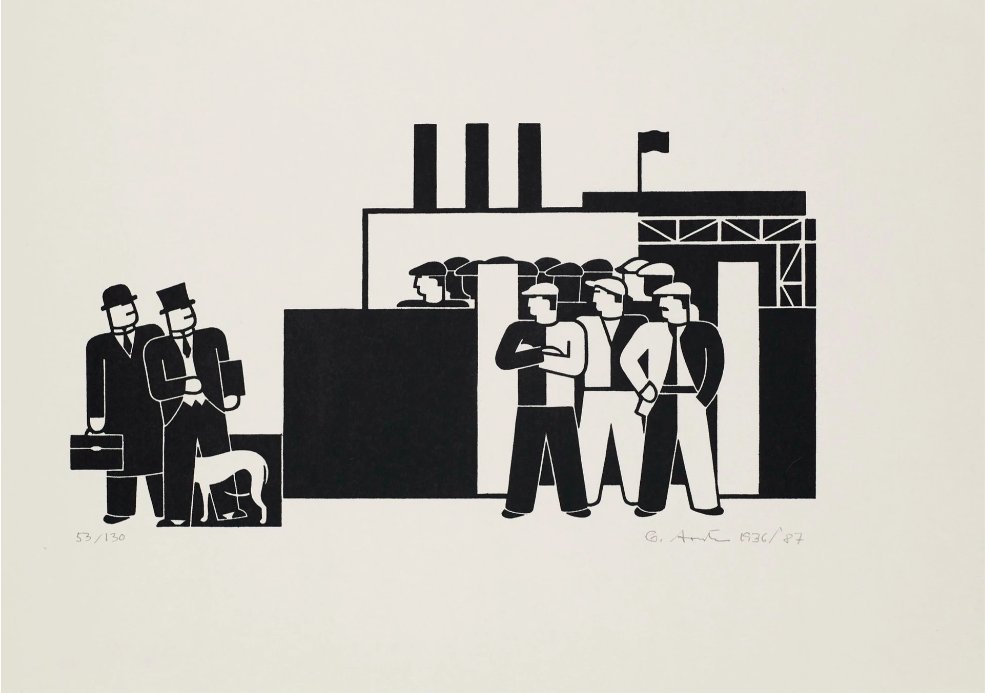

As industry develops, the complexity of production processes naturally tends to increase as new investments create additional demand for new types of production goods. If you were to try to explicitly detail how to produce many modern products of industry, you would find yourself thinking about a huge number of intermediate processes, each of which in turn requires you to think about many more sub-components and how they are made. Soon you would recognize that the task you have undertaken encompasses the consideration of thousands of individual production steps, which must all be arranged in the right proportions and at the right times. In coordinating such efforts, industrial engineers historically have played a special role, which is not only to calculate appropriate production productivities at each stage, but also to continually re-evaluate and improve upon the current ways of doing things, down to the number of seconds that each unique physical movement should take an average production line worker to complete. This is the basis of Taylorist production–workers are like any piece of equipment, which, when combined with other machines and input parts in a certain way, will produce a given number of output parts in a given period of time. A group of experts continually tries to maximize the productivity of labor by rearranging the factors of production.

With that in mind, I invite you to consider for a moment the factory where I work. There are thirteen staff in the department of industrial development, including myself. The number of operators on production lines is, at any time of the day or night, over two thousand personnel, working on hundreds of lines in three shifts. Any given component has to pass through many stages of processing–automated, semi-automated and manual, sometimes multiple times. The level of complexity and variability in the flows of components between these processes makes even the task of calculating the intermediate production outputs on a daily basis well beyond the capabilities of our department, not to speak of studying and improving upon the processes at a micro level. In many modern factories, in other words, the old Taylorist approach is not practicable, and neither, as we shall see, is it desirable. In the field of management cybernetics, we have a special term to describe the problem with which this presents us–we lack the ‘requisite variety’ to control the production processes ourselves. That is, the system is outside the scope of our ability to act upon and regulate effectively.

For decades, this problem of insufficient variety in both the Soviet and Western blocs was mostly ignored by industry in spite of the spiraling complexity of production. Eventually it was explicitly recognized and then addressed by Japan’s Toyota Corporation through their discovery and development of ‘pull’ manufacturing. They knew by looking at major producers in the 1950s that this had become a severe problem, leading to poor quality, dysfunction and enormous waste. Big industries of the US, just as in the USSR, were producing large quantities of defective and unwanted components throughout their supply chains. Toyota understood that future production would only become more complex, and that this situation represented a fetter on further development. To break from it they needed to radically increase the level of complexity which they could handle. Indeed, the solution was immediately clear to them. Simply have the workers on the production lines themselves self-organize three closely linked tasks which had become too complicated for any small group of experts to manage: the calculation of production quantities at every step, the scheduling of staffing production lines, and continual re-evaluation and improvement upon how production processes worked. Doing so would allow the industrial engineers and other specialists to think about the bigger picture and only intervene in day-to-day production strategically when a big change is to be introduced, or when some kind of significant problems or opportunities arise.

Such an obvious solution came with an obvious problem however: unless they are explicitly told by some group of experts, how could production line operators possibly know how much of every component to make, and when? The solution was found in borrowing the concept of supermarket replenishment systems, where individual goods are replaced in small quantities whenever they begin to run low on the shop’s shelves. Treating each stage in a factory like a shelf in a supermarket would mean that replenishment is initiated by consumption, rather than being planned in advance according to a schedule. In applying this idea to a factory, US quality pioneer W. Edwards Deming coined the principle which bears his name: “the next process is the customer.” This means that there is no difference conceptually between a product moving between production lines within a firm, moving between firms, or between a retailer and a final consumer. In any of those cases, the preceding process must always supply product at the rate required by the subsequent process. Changes in demand for final consumption goods therefore act to modify the average production levels of all logically prior processes in the supply chain. This immediately and automatically provides individual production lines and whole factories with quantitative production and scheduling information. Whereas production had become too complex for experts to organize centrally, this method allowed each line to regulate its own supply locally in response to changes in demand from the subsequent step, and unlike the former case, it works regardless of the increasing complexity of the processes.

Within today’s modern factories, Toyota’s Kanban system is often used, where a certain number of ‘baskets’ exist as a buffer between production processes. The ‘supplier’ step can fill up these baskets with products, but must then stop when the baskets are full, placing a hard limit on its overproduction. This limit forces the supplier to synchronize its rate of production with the rate of consumption of its customers. If they produce too quickly, the baskets will all be full, halting further production. If they produce too slowly, the customer will come to take products but find that the baskets are all empty, thereby halting further production at the customer’s step. In either case, the production process in general soon breaks down, as prior and subsequent steps all along the supply chain must also halt their production, either due to a lack of supply from the impacted lines or because their own baskets quickly fill up due to lack of demand from the impacted lines. The key point to understand is that these ‘breakdowns’ act as information signals, telling producers when their local productivity is incompatible with the productivity of the supply chain as a whole.

The Toyota Production System (TPS) not only allowed for production to be self-organized by the supply chain, but also satisfied the condition of enabling self-organized process improvement. For example, industrial engineers found a new role in strategically reducing the number of Kanban baskets existing between production steps. With this reduction in the size of the buffer, any mismatch in productivity causes the baskets to fill up or run empty in a proportionally shorter time. Reducing the buffer size does not cause the required rate of supply, in principle, to either rise or fall, but it reduces the tolerance for error, requiring it to be even more closely synchronized with the customers’ rate of demand, to prevent the supply chain from breaking down. These breakdowns resulting from the smaller buffer size expose structural flaws in the production system, a lack of precision which then becomes the basis for a new round of process improvement. The only way to keep production going under the new circumstances may be to move machinery to different parts of the factory, or to change the sequential order of how some parts are assembled. This can produce very interesting results–I myself have seen how, when productivity at some step in the process is too fast for the supply chain in general, the achievement of synchronization can lead production workers to recommend that a big and modern machine be replaced by a smaller and ‘less efficient’ (but more suitable) one. In this way, new investment decisions are based on the information signals that indicate non-compatibility between local and global productivity levels.

The extent to which the flaws in the process are overcome is reflected in the subsequent reduction in the number of breakdowns, and the return to smoothly flowing production at this now higher level of required precision. Again, because of the complexity of modern production, no one is better equipped than the production operators themselves to understand which changes would need to be made in order to keep their own production line operating without breakdowns. In The Toyota Way, Jeffrey K. Liker describes how “Toyota turned scientific management on its head and turned over control of standardisation to work teams.”1 This new approach at Toyota gave rise to the concept of “responsibility without authority,” a phrase coined by Toyota manager John Shook, which applied to work teams on production lines.2 It was these teams, not managers, who were charged with maintaining the stable functioning of their line within the requirements of the supply chain, and were given responsibility for making necessary changes in production processes accordingly. However, they did not have the ultimate authority to maintain those changes if they conflicted with the wider requirements of the factory’s other processes. In this way, local self-organization of the team was reconciled to the global coherence of the system.

The third critical responsibility which was, by necessity, passed over to the workers on the ground was in the area of line scheduling. Under the TPS, labor needs to continually move about, both due to efficiencies being found at different production lines and also due to fluctuations in demand for the products of each production line. As a result, in many modern factories workers are able to sign themselves onto production lines rather than be assigned to a posting by management. Operators will typically have a ‘home line’ at any given time, and can then ‘unlock’ permission to work on other lines by completing hours of training pertaining to those specific lines. Managers, for their part, monitor the extent to which cross-training has given aggregate numbers of workers the appropriate skills to work on each production line, while also tracking the current required number of operators on each of the lines.

This ‘required’ number of operators for any specific line is, in the factory where I work, based on a simple algorithm which incorporates the average number of workers for whom it is the home line, the rate of absenteeism of those workers, the rate of worker turnover on the line and the volatility of demand for the products of that line. For each of the factory’s production lines, a surplus of workers should be seen to exist within the factory who can potentially sign themselves on and work there, over and above the labor which is thought to be strictly required. Given an adequate skills surplus for each line, the production workers are quite capable of self-organizing their schedules with the help of technology: whenever fewer workers than deemed required are currently scheduled to work on a line, this can be seen on the corporate computer software as a flashing warning indicator, alerting all operators who already have the required training to the possibility to sign onto the line and keep production going smoothly.

Algedonics

A key implication of the self-organization of these three activities–production, process improvement and scheduling–is the profound new importance of what the father of management cybernetics, Stafford Beer, called ‘algedonic signals.’ In a modern context, these signals consist of visual alert icons, again on the corporate computer system, which also generate instant messages by phone and email when activated, and which then require the immediate attention of pre-defined recipients. Such signals are ‘activated’ either manually in light of an immediate problem or automatically, as a result of relevant flows of production statistics crossing over a predefined threshold. These algedonic signals now take on great importance because industrial engineers (as well as other specialists in the fields of quality, safety, and so forth) engage with the pull production system through such exceptional events, when things are going notably well, badly, or when specific classes of issue arise.

In modern factories, when the relevant parties receive such instant ‘algedonic signals,’ they then need to confirm that they will react to them through the corporate computer program, and having done so, they must report on their findings while closing (‘normalizing’) the signal. Both the event and the reaction to it then act as the basis for further discussions and process improvements. Failure by the specialist to react in a timely manner to the problem, or failure to confirm that a problem has been resolved within a given time period, automatically causes the signal to ‘escalate’ to higher levels within the organizational hierarchy, triggering more instant messages. Someone is thus always responsible for any emergent situation, up to and including the top levels of the organization, and inaction as well as any actions constitute information signals which are transparently visible to everyone within the system. The emergent facts of the production process in this way impose accountability on all specialists and managers, subordinating them to the process rather than the other way around.

The Social Relations Bubble

In the decades that followed its initial implementation, pull production kicked off the ‘lean’ revolution in manufacturing. It became clear over time that Toyota’s discovery did indeed hold the key to addressing many glaring problems, evidenced by huge leaps in productivity, efficiency, quality, waste reduction, and so on in many industrial sectors. All of Toyota’s direct competitors (and then many other industries) were forced to copy it to one degree or another, with Kanban bins, algedonics, and so on today being ubiquitous features of mid to high technology manufacturing. Just as Fordist and Taylorist production had revolutionized the workshop-type factories of the early 20th century, Toyota’s system did the same in the century’s later decades. But in doing so, they also discovered something far more profound and interesting.

Toyota tried to understand which conditions were necessary for pull production to produce optimal outcomes. In other words, they knew that their new system operated according to a different set of rules than had been the case in Fordist factories and they tried to determine the optimization parameters which made sense under the new regime. From the very early implementations of the TPS, they found that a certain type of environment needed to be cultivated in order for the system to really succeed, a very atypical environment in the context of wage labor. This environment amounted to cooperative conditions of production,3 which the self-organization of production–the whole point of the TPS–springs out of. They found that the system performs best when individuals freely give their full participation to their work teams, in a cooperative spirit. This is essentially the opposite to the Taylorist conception of a worker being hired to be a very particular cog in a machine, where the optimization parameter is how effectively this individual is atomised so that they follow their foreman’s instructions to the letter.

The self-organization of process improvement, for example, relies on a discovery function which, as we have seen, is operationalized through a feedback loop of continual process refinement, from algedonic signals, to self-organized process improvements, to new algedonic signals. To see why this requires cooperative relations of production, assume that as the factory management you instead decide to pay people a bonus whenever they trigger an algedonic signal and report a problem. You will soon find that the system is inundated with trivial and false reports. Equally, if you punish people for inappropriate reporting, no one will report anything. It is not actually possible in principle to reward or punish people for reacting to events in terms that they themselves are supposed to regard as (in)appropriate, reacts. The only way that people will react appropriately in using an algedonics system is if they themselves actually want to do so. Money and sanction, the traditional tools used to impose the priorities of the business entity onto the individual worker, will actively harm a system based on self-organization. This is another example of management not having the ‘requisite variety’ to effect its control over a system.

Logically however, the attitude of the worker to process improvements (and therefore to using algedonics) should be at best ambiguous and at worst hostile. When a production process is improved, it creates space for the company to realize the efficiency gain as profit by firing any workers who are now surplus to requirements. Under a Fordist and Taylorist production management system, industrial engineers would recommend improvements to production processes in reports to management based on exactly this kind of calculated cost saving. Doing so in the context of the TPS would, however, very clearly damage the motivation of the workers to self-organize further improvements to the production process, as doing so endangers their future employment. The difference in TPS, therefore, is that in contrast to the former case, management now actually needs the workers’ creativity.

The solution that Toyota developed was to institute a sort of ‘social relations bubble’ – to simply protect workers from any negative consequences arising from their self-organized improvements to the production processes, regardless of how costly doing so may appear. They instituted a long standing ‘no layoffs’ guarantee to their production workers, which was observed by the company for many years.4 I think of this guarantee as the ‘golden rule’ of cooperative relations of production, because it means that work teams can freely improve their processes without concern for any negative implications of doing so. Fundamentally, without this guarantee, it is virtually impossible to cultivate cooperative labor conditions. This guarantee, therefore, is essential to the success of self-organized production, because, in the words of management expert Paul Adler, “90% of people, if you give them a chance to work smarter and improve their jobs, and if they find that by doing that they have created free time for themselves, will spontaneously look for new things to do. I’ve got hundreds of examples [my emphasis].”5

This was also Toyota’s conclusion: under the appropriate regime of social relations, people innately enjoy success in challenging situations, especially in the context of group dynamics and teamwork. They found that, using algedonics and the Kanban system, along with the no-layoffs policy, their work teams were extremely innovative at redesigning production processes over and over, in order to keep production going under ever higher standards of precision. This could never have been achieved under traditional means of factory management, which instrumentalizes labor to do a particular and predefined job.

A Fair Day’s Work For a Fair Day’s Pay

Another important optimization parameter within the framework of ‘cooperative relations of production’ was found to be compensation for labor, where greater equality produces a superior implementation of the system. I have seen in my own workplace why equality of income acts as an optimization parameter in this kind of system. Paying people unequally to work on different lines (or, what is the same thing, compensating people with different levels of education and training unequally), systematically makes some tasks attractive relative to others. This introduces a negative incentive into the self-organized work scheduling system, by creating competition for places on certain lines and a scarcity of workers on others. With equal pay, it is relatively easy for workers to share out relatively more and less onerous production roles through cooperation. Cooperative production relations demand equality of payment–payment as participation in teamwork–which in turn reinforces cooperative production relations.

With the protection from layoffs in effect, it is equally in the interest of all workers to figure out how to reduce the existing amount of unpleasant work by finding efficiencies in the tasks that everyone is obliged to do but no one wants to do. If a bonus system is being used instead for workers who are doing unpleasant jobs, it becomes in the interest of the workers to actually maintain the amount of unpleasant work as well as to compete for these better paid roles. Under the TPS, workers are interested in upskilling through training and education not because it increases their individual salary but because it guarantees them the ability to simply switch to other production lines when they raise the process efficiency of their current line, thus removing all apprehensions that would normally exist about full participation in doing so. This is why to be “multi-skilled to work across different manufacturing processes” became “a requirement in Toyota plants.”6 Cooperative relations of production require highly cross-skilled labor, again, the opposite to instrumentalized labor (that which is purchased for a wage to do a specific job).

The experience of the New United Motor Manufacturing Incorporated (NUMMI) factory in Fremont, California is the textbook example of the realization of these policies. Originally owned by GM, its management was then taken over by Toyota in 1984 as part of a joint ownership agreement. It was also a factory with a militant, effective trade union representing its workers, and it was precisely under these conditions that the TPS achieved one of its most pure implementations. The no-layoff policy meant that during an economic downturn in the late 80s, there were at one point 264 more production workers than needed at the plant.7 Toyota maintained this policy regardless, understanding its fundamental importance to the TPS’ underlying social relations of production.

Speaking about pay at the NUMMI plant, one worker commented that “[t]here used to be 80 hourly worker classifications with varying pay rates under the old system. This caused workers to grumble over why one worker got 5 cents an hour more than someone else for what looked like equally strenuous work. We don’t have those kinds of arguments any more. And that makes a big difference to our productivity. Furthermore, there were no more seniority, performance, or merit-based bonuses.”8 In optimizing the conditions for cooperative labor to occur, Toyota agreed with the union that “all production workers get the same hourly rate—currently $17.85—regardless of their jobs, except that team leaders get an extra 60 cents.”9 While all individual bonuses were eliminated, the Toyota company in Japan did pay “a large portion of salary in semi-annual bonuses” which were “tied to company performance, not individual performance.”10 In the factory where I work, a more convoluted pay-scale and bonus system ends up also generating highly equal incomes for production line workers, as a logical consequence of management trial-and-erroring their way to optimizing pull production.

What Toyota had learned, quite by accident, was that when you create a protective ‘bubble’ in which cooperative labor relations can be cultivated, away from the normal logic of the capitalist market, this will systematically outperform production carried out by instrumentalized labor in the long run. Cooperative labor will actually improve on the process itself over time, something previously unimagined. This was found to be qualitatively superior in the same sense that free, waged labor was judged to be more effective than slave labor in an earlier phase of capitalist development.

Suppliers’ Associations

At the macro level, a further optimization parameter which Toyota discovered consists of the fact that pull production works better the more thoroughly it colonizes its own supply chain, remaking it in its own image. Because of Deming’s principle that “the next process is the customer,” Toyota found it impossible to implement their system merely within the limits of their own organization. Whether ‘the next process’ happened to be within the confines of the legal structure of the Toyota corporation or not proved irrelevant to the logic of pull production. A supplier company which operated on the basis of Fordist production would have the same effect as if one of Toyota’s own production lines decided to revert to this earlier form. For Toyota, this meant the return of inefficiency, large inventories, poor quality and the loss of the self-improvement system in that section of their supply chain.

Toyota, as well as other major firms using the TPS and its derivatives, thus each maintain their own “suppliers association.” Members of the Toyota suppliers association for example were required to themselves implement the TPS, in order that Toyota’s own factories would receive goods according to exactly the proportions, schedule, and quality in which they needed them. As described in The Toyota Way, “[s]ince Toyota does not view parts as commodities to be sourced on the market through open bidding, it is critical that it works with highly capable suppliers that are following TPS or an equivalent system.”11 This, therefore by direct implication, is not merely a technical implication but also a social-relational implication, because, as we have seen, TPS has social-relational optimizing parameters.

As Toyota quality manager Don Jackson described, the company had no regard for the independence of their suppliers. They found it necessary to dictate suitable labor conditions and pay rates–not out of some irrational concern for workers in entirely separate companies, but out of intelligent self interest, based on their understanding of what was required for the TPS to work properly:

It was a lot of the human side. You know, salary was too low or overtime was too high, working conditions were poor, there was no training or development plan. There was not good management. So I went ahead and had HR join me on audits of a couple of these critical suppliers. We did a very deep analysis of their organization. We looked at the turnover ratio, what they paid people, how they decide what the pay scale should be in the area. The HR team would investigate training, development, did they have an opinion survey? Etc. So for “SIC” [underperforming] suppliers, HR would do the HR investigation, quality would do a quality audit, production engineering would examine the manufacturing side.12

The macro-level result of this objective need to colonize their own supply chains is that, as supply-chain expert Martin Christopher puts it, “in the 21st century, companies don’t compete, supply chains do.” This statement becomes more true, the more capitalist industry develops along pull production lines and entire supply chains are fine-tuned to work as single systems. The modern online retail giants, with their stock replenishment systems, have also played an important role in forcing their suppliers to produce in a way that is compatible with their requirements.

The Fetters on Pull Production

Pull production emerged in the latter half of the 20th century because the existing relations of production within factories were understood to represent a fetter on the further development of industry. I believe that subsequent experience has proven that cooperative relations of production are indeed superior to those of instrumentalized labor. A company, or even a whole supply chain, may, in contingent and time-limited circumstances, maintain what I have called the ‘social relations bubble,’ as Toyota at times attempted to do, isolating its workers from negative consequences of process improvements. Capitalist imperatives, however, continue to act as a fetter on the further development of pull production itself, preventing it from realizing anything like its true potential.

In the “The Darker Side of Lean,” Darius Mehri explained how in his experience of working for Toyota in Japan, the TPS operated as a system of institutionalized bullying and high intensity labor, in which “workers do not even have a second to wipe the sweat off their faces.”13 I have no doubt that this account, and others like it, are completely accurate in their depictions. Many socialists and trade unionists also, having read such accounts of the TPS, or experienced it as such themselves, have come to view it as a system of hyper-Taylorism, and have condemned it on that basis. It must also be recognized, however, that such cases are in total contradiction to the logical operation of pull production and TPS as understood by those who developed it. Management can certainly manipulate the pull system in such a way that workers need to labor as intensively as possible, but in doing so, they destroy the self organization and automatic discovery process which is the greatest strength of the TPS. As I have mentioned already in terms of incentives, no worker would use a system of algedonics, so critical to the discovery process, if they could be punished in an oppressive environment for doing so. There are many examples of massive participation by workers in factories using the TPS, where the ‘continual improvement’ process, as it is known, really does work. These counter-examples where operators are instrumentalized like work animals merely represent a lurch backwards, away from the simulation of cooperative labor conditions, to the well-known unproductive, inefficient, error-prone practices of the early 20th century.

These lurches backwards are not the result of simple stupidity by factory management. They find themselves responsible to the corporation, and so long as capitalism exists, capitalist imperatives will continue to make themselves felt in all kinds of ways, moving industry further away from the promise which pull production holds. The Toyota corporation itself has, in recent years, partially abandoned its own supply chain association in a scramble to increase its market share and profits, resulting directly in poorer quality and mass recalls.14 It has in recent years breached the ‘no layoffs’ policy which it itself says is fundamental to its success,15 as it feels pressure to cut costs in competition with rivals. It is always an imperative in capitalism, from lenders, shareholders and so forth, to sacrifice long term development in favor of short term profit. Only in an economy of generalized cooperative production relations can these fetters be finally broken from, with the help of the cybernetic management systems that already exist and that we already know can facilitate its successful realization.

Implications For Socialism

Pull production in the circumstances of socialized industry would, I believe, be used just as in modern factories and supply chains, but without the contradicting social relations which hold back its development. The problems of economic organization would be solved through the local regulation of rates of supply, but now under the generalization of conditions best suited to stimulate cooperative relations of production. The levels of labor productivity which are required by the economy as such would not be dictated by profit and competition but rather by information signals given directly by production itself, propagating through supply chains, like sensory nerves in the body. Supply chains would become fully integrated single systems to a much greater extent than today. A single integrated algedonics system in the context of socialized production would mean that any notable events in production anywhere are responded to immediately and incorporated into how the system works, creating a finely tuned machine of mutually interdependent associated producers.

Today factory algedonic systems exist only as their own small islands in the economy, while the vast majority of producers are tiny in scale and separated by relations of private property, and so cannot establish such systems. In a socialized economy, any bakery or repair shop would use algedonics just as a factory work-team does today, to normalize any emergent problems and standardize the most precise cooperative methods of working. What appears under capitalism to any given producer as a huge number of competitor or indifferent firms would be transformed into an inexhaustible source of material assistance and technical knowledge, subordinated to each other’s needs. Meanwhile factory production scheduling, taken to the social level, would mean that, in contrast to a situation like in East Germany where a state builds a wall to prevent its workers from leaving (while keeping many more employed in make-work), the problem of a high turnover of labor, to whatever extent it exists, is tackled just as in modern factories. The turnover rate is simply accounted for in advance algorithmically for the self-organized scheduling system, ensuring that training and education maintains a persistent local skills surplus in each area. This implies that socialism requires not only the generalization of a suitable environment for cooperative labor to flourish, but also a highly skilled population compared to that required by a capitalist economy.

In summary, by looking at how modern industry is organized, we can see that it is precisely those same conditions which are required to overcome the remaining fetters on production today which are also the basic requirements for the establishment of communism: the de-alienation of labor, the self-organization of production processes by the direct producers, and the cybernetic systems which facilitate both.

- Jeffrey K. Liker, The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer (New York, NY: McGraw-Hill, 2003), 197.

- Ibid, 179.

- “One of the paradoxes of lean thinking is that the ideas themselves are extraordinarily antihierarchial and pro-democratic. Every worker inspects his or her own work, becomes multiskilled and participates in periodic job redesign through Kaizan activities.” See: James P. Womack & Dan Jones, Lean Thinking: Banish Waste and Create Wealth in Your Corporation (New York, NY: Free Press, 1996), 268; “While Taylor strictly focused on individual incentives for productivity, Toyota distributes work to teams. Groups, not individuals, take on responsibility. Performance measures are about how the group is doing…” See: Liker, 197.

- Joe Weisenthal, “Toyota Tries To Avoid Layoffs, Wage Freezes And Shorter Work Weeks Instead,” Business Insider, February 13, 2006, https://www.businessinsider.com/toyota-tries-to-avoid-layoffs-wage-freezes-and-shorter-work-weeks-instead-2009-2.

- Paul Adler, “Time-and-Motion Regained,” quoted in Robert B. Austenfeld, Jr., “NUMMI–The Great Experiment,” Papers of the Research Society of Commerce and Economics 47, no. 2 (2006), 78.

- Liker, 97.

- Austenfeld, Jr., 61.

- Ibid, 63.

- Paul Adler, “Time-and-Motion Regained,” Harvard Business Review Magazine, January–February 1993, https://hbr.org/1993/01/time-and-motion-regained.

- Liker, 300.

- Ibid, 210.

- “Saving ‘Sick’ Suppliers Through TPS,” https://www.ineak.com/saving-sick-suppliers-through-tps/.

- Darius Mehri, “The Darker Side of Lean: An Insider’s Perspective on the Realities of the Toyota Production System,” Academy of Management Perspectives 20, no. 2 (May 2006), 25.

- “Takahiro Fujimoto, a leading Japanese researcher on Toyota, reports that in the wake of rapid growth, Toyota increasingly failed to properly evaluate and approve components designed by outside overseas suppliers. As a result, Toyota’s relationships with suppliers became less collaborative, thereby weakening the company’s distinctive “relational contracting” system characterized by long-term close OEM [Original Equipment Manufacturer] relationships with suppliers. Ironically, it was the collaborative practices that had originally distinguished Toyota from its Western competitors.” See: Robert E. Cole, “What Really Happened To Toyota,” MITSloan Management Review, 52, no. 4 (Summer 2011).

- Yusuke Hinata, “Toyota slashes 1,000 jobs at Operations in China,” Nikkei Asia, July 25, 2023, https://asia.nikkei.com/Business/Automobiles/Toyota-slashes-1-000-jobs-at-operations-in-China.